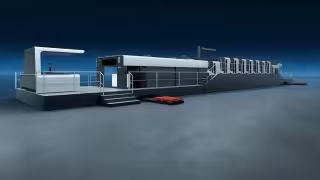

HEIDELBERG Launches Cartonmaster CX 145 to Strengthen VLF Folding Carton Printing Portfolio

SHERIDAN, WYOMING – June 3, 2025 – Heidelberger Druckmaschinen AG (HEIDELBERG) has introduced the new Cartonmaster CX 145, a very large format (VLF) sheetfed offset press aimed at the high-growth folding carton printing sector. The move strategically positions HEIDELBERG as a full-range supplier for packaging print solutions, aligning with its long-term growth strategy and marking a significant milestone in its 175th anniversary year.

Strategic Entry into Format Class 6 Press Market

Folding carton printing for food, beverage, and consumer packaging continues to see above-average annual growth, particularly in long-run production using format class 6 (105 cm × 145 cm / 41.34 × 57.09 in) sheetfed offset presses. In response, HEIDELBERG is broadening its packaging portfolio to include this segment.