SIPA’s Sincro Tribloc Redefines PET Bottling with Fully Integrated High-Speed Line

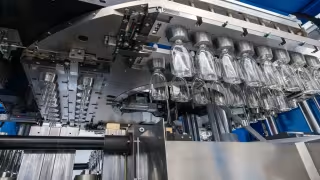

SHERIDAN, WYOMING – October 15, 2025 – SIPA has introduced the Sincro Tribloc, a fully integrated PET bottling solution that combines blowing, labelling, and filling in one compact unit. Designed for ultra-high-speed operations of up to 90,000 bottles per hour, the system redefines efficiency and sustainability standards for beverage manufacturers seeking leaner production and reduced total cost of ownership.