SHERIDAN, WYOMING - December 2, 2025 - Swiss communications provider rubmedia has commissioned a compact, highly automated Heidelberg digital print line at its new site in Köniz near Bern, combining a Jetfire 50 inkjet system, a Versafire LV toner press and integrated workflow software to industrialize personalized short-run production.

Digital production line anchors new Köniz facility

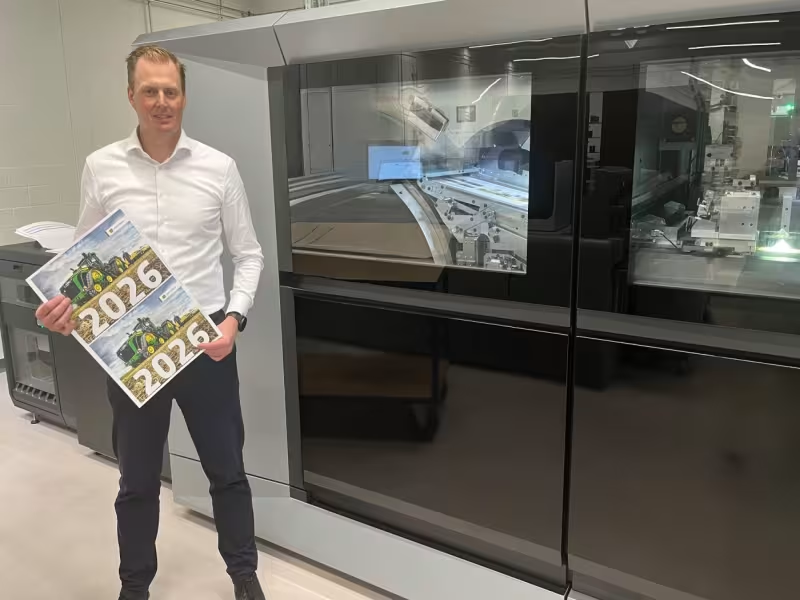

With around 35 employees, rubmedia positions itself as a media house focused on creative communication solutions for service providers, industry, associations and political customers. As part of an internal transformation project linked to its relocation, the company rethought its production strategy and installed a tightly integrated digital line designed for efficiency, quality and automation.

At the heart of the new setup are the Jetfire 50 and Versafire LV from Heidelberger Druckmaschinen AG (HEIDELBERG), complemented by in-house finishing equipment from a third-party supplier. The Köniz operation is geared primarily toward personalized print products and ever-smaller runs with high expectations on creativity, turnaround speed and image quality, while the Versafire LV also handles standard applications such as business cards, envelopes and flyers.

End-to-end workflow with Prinect Business and Production Manager

Beyond the presses themselves, rubmedia's key requirement was end-to-end integration-from order entry through production to finishing. To achieve this, the company is automating both its commercial and production workflows using Heidelberg's Prinect Business Manager and Prinect Production Manager.

With Jetfire and Versafire tightly embedded in this Prinect environment, rubmedia has realized a continuous workflow that covers the full job lifecycle. Orders flow from the front end into automated planning, imposition and press scheduling, then on to connected finishing, reducing touchpoints, media waste and manual interventions while supporting consistent quality at industrial production speeds.

Service promise and integration drive vendor choice

The decision to choose Heidelberg's digital solutions was shaped as much by service and integration as by print engine specifications. „Wir haben uns für die Digitaldrucklösungen von HEIDELBERG entschieden, weil uns das umfassende Serviceversprechen des Unternehmens und die Integrationsfähigkeit der Systeme in einen Gesamtworkflow mit Prinect überzeugt haben. Die Automatisierung ermöglicht einen schnellen Auftragsdurchlauf, reduziert Makulatur und sorgt für eine Qualität, die dem Offsetdruck in nichts nachsteht," sagt Michel Kläy, stellvertretender Geschäftsführer und Partner bei rubmedia.

For a relatively small but quality-driven provider, the ability to rely on a single partner for hardware, software and lifecycle support was a strategic factor. The new line enables rubmedia to keep the entire value chain-from creative concept to finished product-under one roof, supporting predictable lead times and competitive unit costs even for complex, personalized jobs.

Digital ecosystem for personalized, high-value short runs

Heidelberg sees the rubmedia installation as further validation of its industrial digital strategy in Switzerland. „Die nächste erfolgreiche Installation eines Jetfire Systems in der Schweiz unterstreicht die Stärke unseres industriellen Angebots. Unsere Kunden sind zunehmend von unserem digitalen Ökosystem überzeugt - insbesondere für Anwendungen mit personalisierten bzw. hochwertigen Kleinauflagen," so Dr. David Schmedding, Vorstand Technologie & Vertrieb bei HEIDELBERG. „Unser Versprechen lautet: Best-in-Class Service, End-to-End-Integration und ein hoher Automatisierungsgrad für eine wirtschaftliche Druckproduktion."

As demand for personalized communication and premium short runs rises, particularly among corporate, association and political clients, the combination of inkjet, toner and smart workflow gives rubmedia the flexibility to match substrate, format and run length to the most efficient process-without compromising brand consistency or service levels.

Heidelberg positions as system provider for digital and hybrid print

For Heidelberg, projects like rubmedia align with its broader ambition to act as a full-system provider in packaging and digital print, linking presses, workflow, software and lifecycle services into a digital ecosystem. The company continues to expand into adjacent industrial fields such as high-precision equipment, automation and robotics, while maintaining its core focus on productivity, efficiency and reliability in print production.

In the Swiss market, the successful commissioning of Jetfire 50 and Versafire LV at rubmedia underscores how medium-sized media houses can use industrial digital technology and integrated workflows to bring previously outsourced or fragmented processes in-house, building more resilient, profitable and responsive print operations.

For further information on Heidelberg's Jetfire, Versafire and Prinect solutions, visit https://www.heidelberg.com.